Our Process

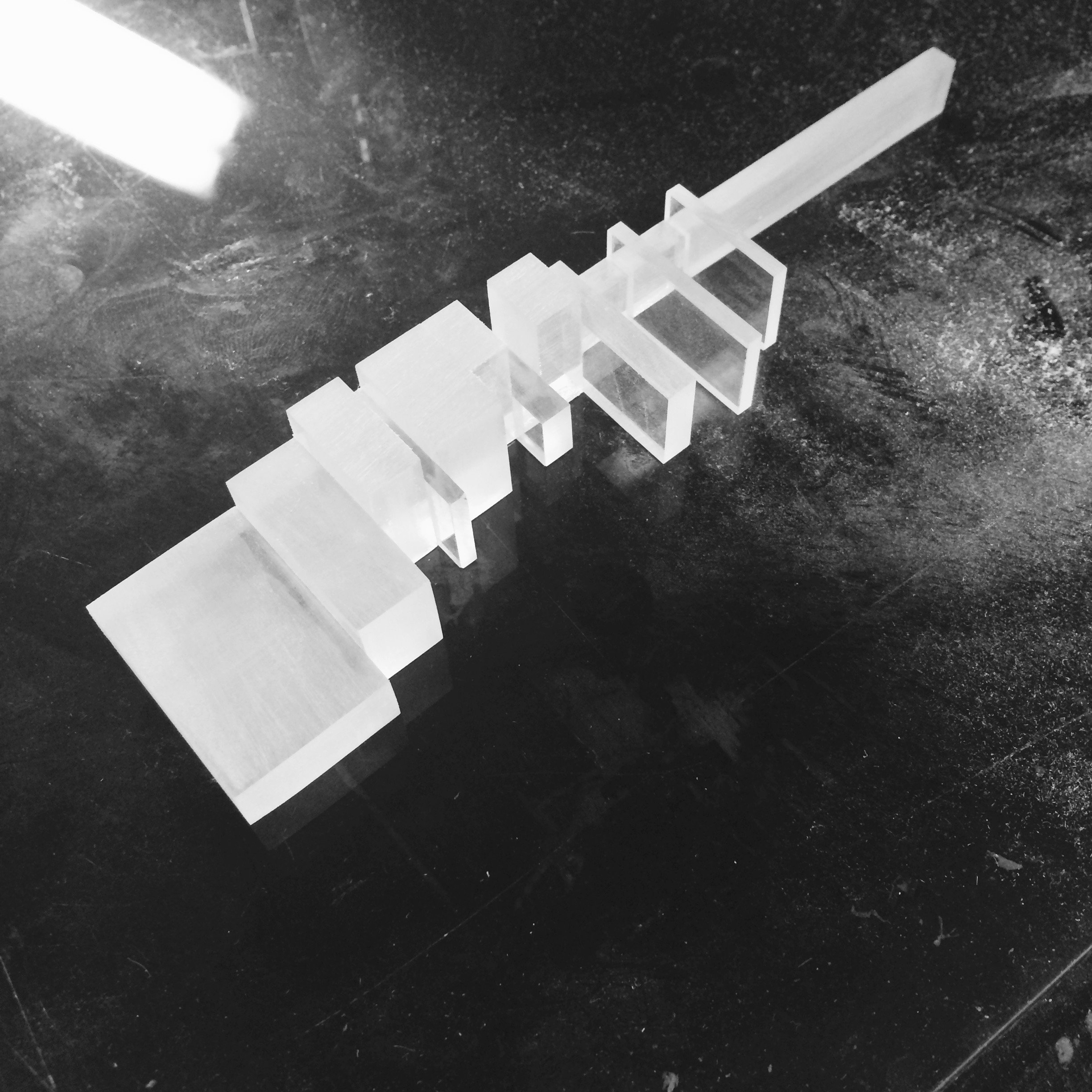

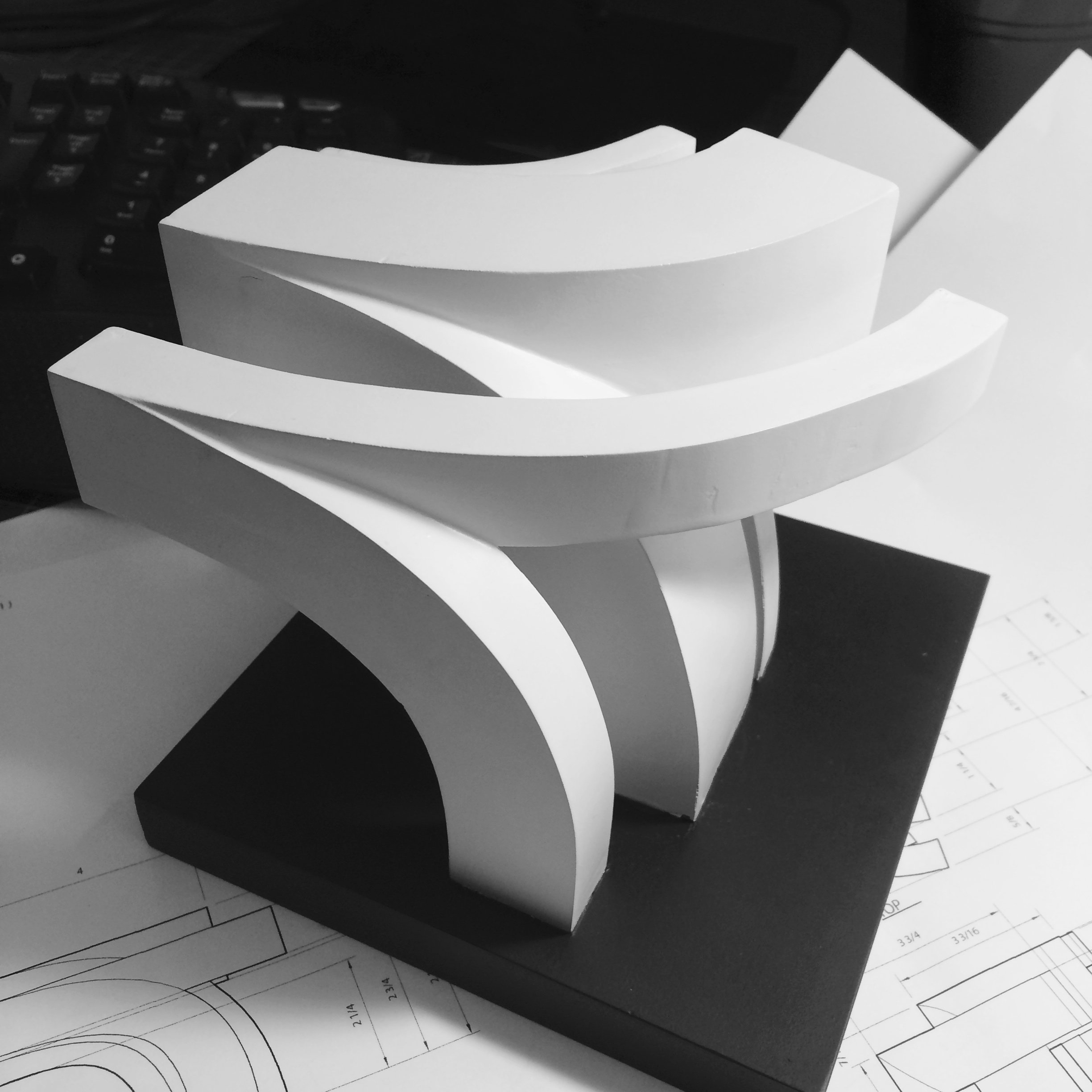

Prototyping is the best way to ensure there are no flaws or hiccups during the manufacturing process. At Gradiant, we work with our clients during the initial conceptual phase and throughout the R+D process, until we develop a working model. Before starting any project that might undergo a prototype, we first schedule a consultation and asses the project needs. From there, we develop schematic drawings and work with the client to digitize it three-dimensionally.

Benefits of Prototyping

Allows companies to test out their product in a “ real-world” environment.

Designers can interact with the design and troubleshoot / improve any problem areas.

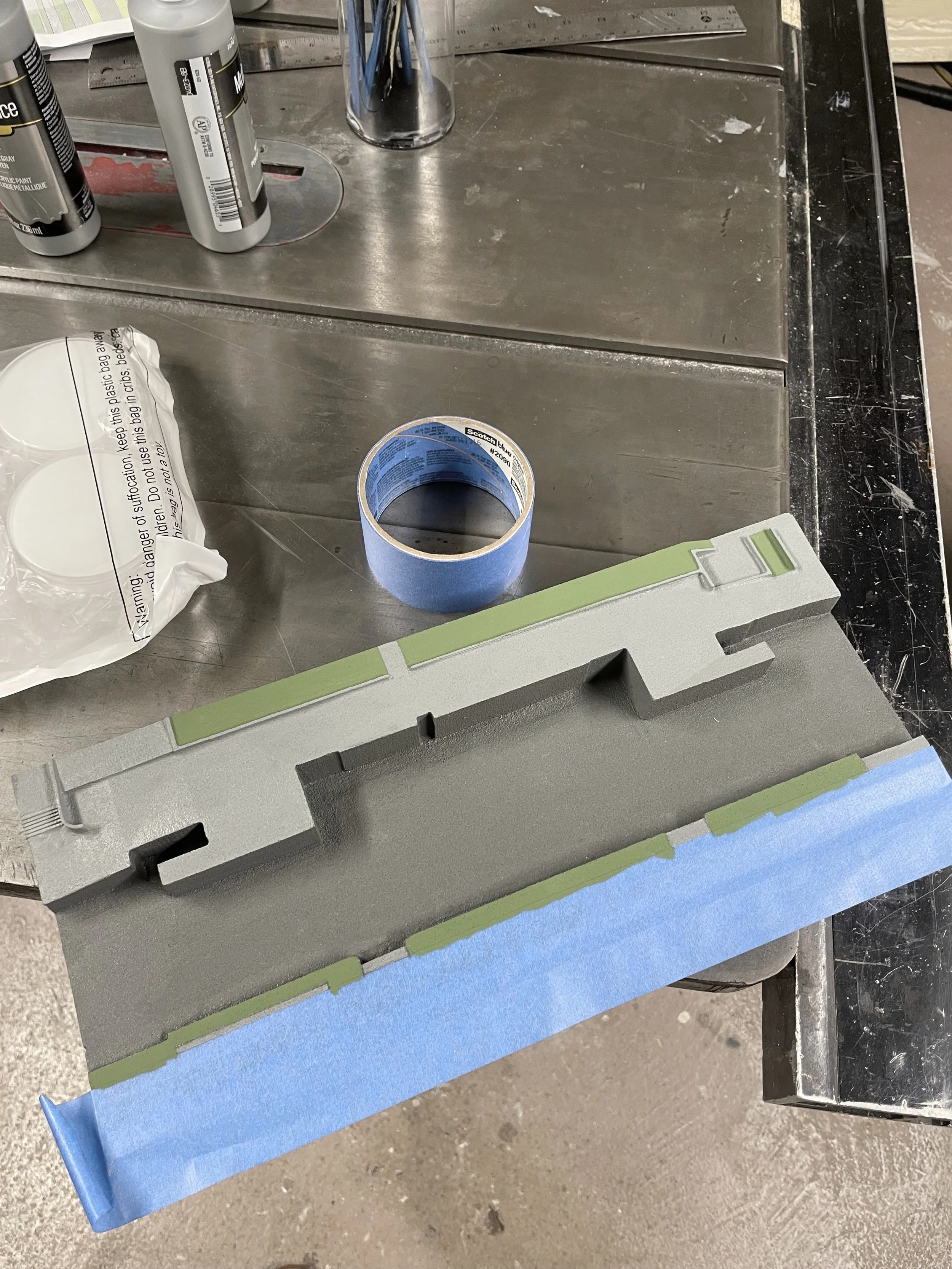

Test out multiple materials to get the right look, feel and how it will behave in the physical world.

Let’s make something!

It all begins with an idea. Maybe you want to launch a business. Maybe you want to turn a hobby into something more. Or maybe you have a creative project to share with the world. Whatever it is, let us help you make the vision a reality.

Experimental testing.

We go through extensive testing with each product we build. Before we build the final product we use advance technologies such as cnc milling / laser cutting / 3D printing to replicate a 1:1 scale mock-up.